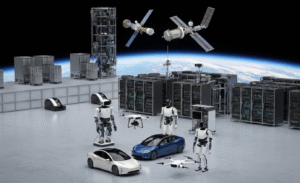

Did you know one company serves more than 75 major firms across automotive, HVAC, refrigeration, and appliances from a single 26,000+ sq. ft. campus?

Future Technologies, Inc. turns innovation into repeatable systems. The company offers custom leak testing, function testing, welding and assembly automation, plus calibrated standard leaks. These services match engineering rigor with real-world production needs.

We map development from concept through commissioning, using verified data and standardized review steps. This approach shortens time-to-value and keeps audits simple. Unlimited at-no-charge training and 24/7 availability lower adoption friction for customers.

Expect a clear view of how development, manufacturability, and field-proven methods reduce risk. The result is faster integration, better quality, and measurable outcomes for regulated and advanced industries across the United States.

Key Takeaways

- Scale and reach: 26,000+ sq. ft. campus serving 75+ major firms.

- Proven systems: calibrated leaks and automation that stand up to audits.

- End-to-end development: concept, engineering, build, and commissioning.

- Data-driven: verified results that reduce risk and speed adoption.

- Customer support: unlimited training and 24/7 availability.

Partnering on Future Technologies to Accelerate Real-World Outcomes

Collaborative engineering and disciplined development bridge lab innovation to reliable field operations.

We embed mission priorities from day one. Our team aligns engineering and development plans with program goals to speed adoption and reduce deployment risk.

We scale across software development, network and computer operations, and systems engineering to meet strict security and performance demands. Intelligence workflows are built in so data handling, access, and reporting follow compliance and secure operations.

- Proactive support: Pre‑, during-, and post‑commissioning assistance keeps capabilities mission-ready.

- Validated delivery: Development sprints sync with validation gates to preserve quality and safety.

- Flexible resourcing: Surge engineering and program management maintain schedules without sacrificing standards.

Our partnership model turns complex requirements into executable roadmaps that connect lab insight to field reality.

Where Future Technologies Deliver Value Today

Practical deployments are closing the gap between lab research and measurable operational gains across several sectors.

Electronics, IT, and Communications

Quantum cryptography is already commercialized for secure links, while quantum computing remains in staged experiments and early commercialization. Organizations can pilot quantum-safe architectures now by combining commercial cryptography with controlled compute experiments.

Energy and Power

Smart-grid upgrades are diffusing across utilities and offer immediate resilience benefits. Lithium iron phosphate batteries are production-ready; solid-state cells and fusion projects remain experimental but worth evaluating in parallel development programs.

Materials and Manufacturing

Graphene sensors and quantum-dot displays have real-world traction. Teams should plan pilots for 4D printing and self-healing materials as their development pathways mature for harsh environments.

Medicine and Bioengineering

Robotic surgery is in broad diffusion, and oncolytic virus therapies are commercialized in select markets. Synthetic biology and precision medicine pilots need strict data governance to move from trials to practice.

Neuroscience and the Economy

Brain-computer interfaces are moving toward market use. At the same time, digital wallets and CBDCs are being adopted, changing how transactions and identity interoperate at scale.

| Domain | Maturity | Immediate Action | Validation Focus |

|---|---|---|---|

| Electronics & IT | Commercialized to early diffusion | Pilot quantum-safe links | software, computer architecture |

| Energy & Power | Diffusion with experimental projects | Upgrade smart-grid modules | control systems, integration |

| Materials & Manufacturing | Range: experiments to early uses | Deploy graphene sensors | material testing, production readiness |

| Health & Bioengineering | Trials to commercial therapies | Expand robotic surgery pilots | data governance, clinical validation |

Recommendation: sequence near-term deployments (machine vision, LFP batteries) alongside exploratory pilots (optical computing, fusion) and validate software and control architectures early. Building a curated range reduces risk and turns development into measurable outcomes.

Government and National Security Solutions Built on Emerging Technology

Federal missions demand hardened systems that deliver secure data handling where infrastructure is limited. FTI strengthens the national security posture for government customers by analyzing intelligence in the field and supplying hands-on expertise in engineering, network and computer operations, and software development.

Analyzing Intelligence Data in the Field with Secure Computer Operations

We enable teams to collect, process, and transmit imagery, signals, and text without compromising chain of custody. Our pipelines shorten time-to-insight while preserving access controls and audit trails.

Field analysis uses hardened compute platforms and continuous logging to support rapid forensic review and operational decisions.

Engineering, Software Development, and Network Operations for Mission-Critical Systems

Our approach fuses engineering and development lifecycles with accreditation, hardening, and testing milestones aligned to security requirements.

Computer and network operations deploy resilient connectivity for forward users. Redundancy and zero-trust design reduce exposure and sustain uptime under stress.

- Secure architectures that protect integrity in austere conditions.

- Governance frameworks that map mandates to development workflows and continuous evidence.

- Tailored deployments with cross-trained teams who sustain, triage, and update under tight windows.

- Scalable model for pilots to mission-critical systems that shortens authority-to-operate timelines.

Quality Assurance and Production Automation for Advanced Industries

When assembly lines demand repeatable accuracy, tailored QA and control systems deliver. Our approach pairs rigorous development with hands-on production tooling to keep yields high and variation low.

Custom Leak Test Systems Designed to Your Specifications

We design a custom leak test system that integrates fixtures, sensors, and software for precise control and repeatable results in high-volume lines. No part-size limits mean the same architecture serves small components and large assemblies.

Leak Testing Methods: Vacuum, Pressure, and Mass Spectrometer Capabilities

Our portfolio spans twelve methods, from hard vacuum mass spectrometer techniques to pressure decay and residual gas analysis. This range lets teams balance speed and sensitivity for each product.

Submersion Helium Leak Tests and Permeation Analysis Unavailable Elsewhere

Submersion helium testing finds defects in complex geometries where other tests fail. Permeation analysis separates background diffusion from true leaks to cut false fails.

Function Testing, Welding, and Assembly Automation at Scale

We build unified cells that combine function testing, welding, and assembly automation. Each deployment includes clear procedures and unlimited operator training at no charge.

| Capability | Primary Method | Best Use Case | Benefit |

|---|---|---|---|

| High-sensitivity leak detection | Hard vacuum + mass | Hermetic enclosures | Pinpoint leaks, low ppm |

| Immersion & permeation | Submersion helium | Complex assemblies | Distinguish permeation vs leak |

| High-throughput checks | Pressure decay / sniffing | Production lines | Speed with adequate sensitivity |

| Integrated production cell | Function + welding automation | End-of-line validation | Reduced handling, consistent quality |

Industries We Serve Across the Technology Lifecycle

Sealing integrity affects everything from EV battery trays to medical enclosures. Our work supports design-for-testability during development so teams avoid late-stage redesigns and delays.

Automotive, Powertrain, Fuel Systems, and EV Battery Trays

Automotive and powertrain programs rely on our systems for sealing validation of fuel rails, EV battery trays, and precision components. These checks reduce risk and protect safety-critical parts in production.

HVAC, Appliances, and Energy Distribution

HVAC and appliance clients use our methods to ensure coil, compressor, and enclosure integrity. Energy distribution applications use robust fixtures and cycles to sustain uptime on the shop floor.

Medical Devices and Computer Peripherals

Medical device makers get validated processes and documentation that meet regulated expectations while keeping throughput for sterilizable assemblies.

Fire Abatement and Safety Components

Fire abatement and safety components need strict acceptance criteria. Our engineering teams tailor methods to meet tight tolerances and audit requirements.

With more than thirty years of program experience, we support a wide range of part sizes and materials so a single test strategy can scale with product lines.

| Sector | Primary Need | Key Benefit |

|---|---|---|

| Automotive & Powertrain | Sealing validation for safety parts | Reduced recalls, safer systems |

| HVAC & Appliances | Integrity of coils and enclosures | Lower warranty exposure, higher efficiency |

| Medical & Peripherals | Regulatory documentation and throughput | Compliance and reliable production |

| Fire & Safety | Stringent acceptance testing | Audit-ready results, certified tolerances |

Why Choose Our Team: Engineering Depth, Range of Tests, and 24/7 Support

Hands-on engineers and test specialists work together to turn unusual sealing problems into repeatable production checks. Our approach pairs practical development with measurable system design so you get solutions that last.

Twelve Leak-Testing Methods, No Part-Size Limitations

We offer twelve distinct tests that span sensitivity and throughput. That variety means you select the right method for each product rather than forcing a one-size-fits-all fix.

There are no part-size limits. Our fixtures and software scale from tiny components to large assemblies without redesigning the core test approach.

Unlimited On-Site Training at No Charge and Rapid Problem Resolution

Unlimited on-site training at no charge keeps operators and maintenance staff confident across shifts. Clear procedures and standardized spare parts cut downtime.

- 24/7 availability: rapid support to resolve problems and protect delivery commitments.

- Joint review: we conduct design and results review with your quality and manufacturing engineers.

- Standardized development: spare parts, software configs, and procedures simplify lifecycle maintenance.

“We take on projects others refuse, turning edge cases into maintainable, scalable solutions.”

The result: lower total cost of ownership, faster time-to-stable production, and integrated health and safety features without sacrificing detection speed.

Facilities, Certifications, and Standardized Procedures You Can Trust

A single, purpose-built campus gives our teams room to prototype, test, and validate systems under production-like conditions.

Our nationally based, 26,000+ sq. ft. campus in Bay City, Michigan supports parallel development lines and full pre-shipment validation. Controlled environments and calibrated equipment ensure factory acceptance testing mirrors your site.

26,000+ Sq. Ft. Engineering and Production Campus

Space and infrastructure let us build fixtures, run production pilots, and compress time-to-first-good-part. Documentation packages—drawings, PLC code lists, and operator manuals—are produced under controlled review to support audits and training.

MMSDC Certification and Consistent, Identical Review Standards

MMSDC certification affirms ownership and operational standards that support supplier diversity goals. Standardized procedures and identical review practices across the NMSDC network give stakeholders consistent quality and governance.

| Feature | Benefit | Impact |

|---|---|---|

| Parallel development lines | Faster iteration on fixtures and controls | Shorter schedules, lower risk |

| Controlled factory testing | Calibrated equipment, repeatable results | Predictable performance on delivery |

| Built-in security | Physical access controls and secure data handling | Protects IP and test records |

| Years of program experience | Logistics and installation planning | Minimized on-site footprint and commissioning time |

The outcome is simple: tested systems, verified procedures, and compliant documentation delivered with consistent quality and reduced commissioning risk.

From Concept to Commissioning: A Proven Process for Future-Focused Systems

A governed development path aligns design, testing, and production to meet target throughput. This approach creates clear handoffs and repeatable checks so teams move confidently from idea to operations.

Discovery, Design, and Engineering Review with Clear Procedures

Discovery sets the baseline: part drawings, allowable leakage, takt time, and acceptance criteria. That baseline informs engineering reviews and creates traceable requirements.

Design turns requirements into fixtures, sensors, and control strategies while validating gage R&R and serviceability.

Build, Integration, and Mass Test Operations

Build follows structured checkpoints: mechanical fit-up, electrical panel validation, PLC/HMI development, and interlock verification.

Mass test operations simulate line cadence to confirm stability, alarms, and data capture under production-like loads.

Deployment, Ongoing Support, and Continuous Improvement

Deployment includes installation planning, commissioning scripts, and operator certification to hit throughput quickly.

Ongoing support blends remote diagnostics with on-site service and spares plans. Continuous improvement uses captured data to refine recipes, update firmware or PLC logic, and optimize cycle time without losing sensitivity.

- Change management preserves traceability for audits and requalification.

- Control plans map to FMEAs and process flow to mitigate high-risk failure modes.

| Phase | Key Activities | Outcome |

|---|---|---|

| Discovery | Requirements, drawings, acceptance criteria | Traceable engineering baseline |

| Design | Fixture concepts, sensors, control strategy | Serviceable, validated tooling |

| Integration & Test | PLC/HMI, interlocks, mass test cadence | Stable, production-ready system |

| Deployment & Support | Commissioning, training, spares | Fast ramp, low downtime |

“A governed pathway from development to stable operations reduces rework, accelerates ROI, and keeps production predictable.”

Results That Matter: Security, Compliance, and Production Readiness

Tangible results show up as improved security, higher yields, and predictable time-to-revenue for mission and industry teams.

For federal programs, strengthened architectures and disciplined delivery raise mission performance while meeting strict compliance benchmarks.

Strengthening National Security Posture and Mission Performance

FTI strengthens national security posture by combining secure computer workflows, hardened networks, and rapid personnel deployment.

Verified data capture and automated records support audits and evidentiary chains for sensitive programs.

Driving Yield, Reducing Defects, and Accelerating Time to Production

In manufacturing, twelve leak-testing methods—including submersion helium and permeation analysis—reduce false fails and scrap.

Unlimited training and 24/7 availability speed troubleshooting and stabilize lines so first-pass yield improves.

- Integrated analytics enable faster diagnostics and predictable output.

- A broad range of test modalities lets teams select the right approach per part family.

- Disciplined development shortens the path from FAT to stable production.

“Secure computing, proven test methods, and continuous operator coaching translate into measurable readiness and lower total cost.”

Conclusion

,

Close the gap between lab promise and shop-floor performance with proven engineering and repeatable tests. Our 26,000+ sq. ft. campus, MMSDC certification, and twelve leak-testing methods — including submersion helium and permeation analysis — back measurable results.

We serve 75+ clients across automotive, HVAC, appliances, medical, energy, and safety sectors. Unlimited training at no charge and 24/7 support reduce adoption friction and speed commissioning.

Government and enterprise teams get integrated capabilities: secure computer workflows, software development, network operations, and in-field intelligence to meet mission demands.

Contact us to scope a pilot or discuss how selected systems and engineering choices can raise yields, protect operations, and deliver verifiable outcomes on the plant floor or in the field.

FAQ

What services do you provide for electronics, IT, and communications?

We deliver system design, secure software development, AI and quantum-ready integrations, and cybersecurity for mission-critical electronics and communications. Our team handles network operations, secure computer deployments, and intelligence-data processing to meet government and commercial requirements.

How do you support energy and power projects like grid modernization and storage?

We develop advanced storage solutions, support fusion research test programs, and implement smart-grid controls. Engineering covers powertrain analysis, energy distribution systems, and testing for resilience and compliance.

What materials and manufacturing capabilities do you offer?

Our services include materials selection for graphene and other advanced substrates, 4D printing prototyping, and development of self-healing structures. We combine manufacturing engineering, welding automation, and assembly line integration to scale production.

Do you work on medical devices and bioengineering projects?

Yes. We support medical device design, robotics for surgical and diagnostic tools, personalized-care systems, and synthetic biology workflows. Our quality assurance and regulatory testing help devices reach production readiness.

How do you apply neuroscience-related tech in economic systems?

We integrate brain-computer interface R&D with secure transaction platforms, digital wallets, and central bank digital currency (CBDC) experiments, always emphasizing privacy, security, and compliance with financial standards.

What solutions do you offer for government and national security clients?

We provide secure engineering, hardened software, and network operations for mission-critical systems. Capabilities include field intelligence analysis, secure computer operations, and tailored support for defense and civil agencies.

What leak-testing methods are available and how do they differ?

We offer twelve leak-testing methods, including vacuum decay, pressure decay, tracer-gas mass spectrometry, and submersion helium tests. Each method suits different materials, tolerance levels, and production rates; we recommend the optimal approach after review.

Can you perform helium submersion and unique permeation analyses?

Yes. Our lab performs helium submersion leak testing and specialized permeation analysis that many suppliers do not provide. These services support high-reliability sectors like medical devices, fuel systems, and aerospace.

How do you handle function testing and assembly automation for large production runs?

We design automated test stands, integrate welding and assembly robots, and create scalable inspection routines. Our systems focus on yield improvement, defect reduction, and repeatable cycle times for mass production.

Which industries do you serve across the lifecycle?

We serve automotive (powertrain, EV battery trays), HVAC and appliances, energy distribution, medical devices, computer peripherals, and fire abatement and safety components—supporting concept, test, and production phases.

What distinguishes your team’s engineering depth and support?

Our engineers have broad domain experience across systems engineering, control systems, and production testing. We provide 24/7 technical support, rapid problem resolution, and unlimited on-site training at no additional charge.

Are there part-size limitations for your leak-testing services?

No. We accommodate components of virtually any size, from small valves to large assemblies, thanks to flexible fixturing, custom test enclosures, and multiple test modalities.

What certifications and facilities back your work?

We operate a 26,000+ sq. ft. engineering and production campus with nationally based operations. Our processes follow standardized review procedures and include minority supplier certifications such as MMSDC where applicable.

How do you manage discovery, design, and engineering review for complex projects?

We use a structured process: discovery workshops, requirements capture, iterative design reviews, and formal engineering verification. Clear procedures and documentation ensure traceability and stakeholder alignment.

What does your build, integration, and mass-test process include?

Build and integration include prototype fabrication, system-level assembly, automated functional testing, and high-throughput mass-test operations. We validate performance, safety, and compliance prior to deployment.

What post-deployment support and improvement services do you provide?

We offer ongoing maintenance, remote and on-site support, defect analysis, and continuous improvement programs. Our goal is sustained mission performance and accelerated time to production.

How do your services improve security, compliance, and production readiness?

By combining secure engineering practices, rigorous testing, and standardized quality controls, we reduce vulnerabilities, ensure regulatory compliance, and increase manufacturing yield and reliability.